15 Aug 2025

Min Read

From Minutes to Milliseconds: Slashing Waste and Boosting ROI with Real-Time Quality Control

Table of contents

- The High Cost of a Slow "No"

- The Solution: A Central Nervous System for the Smart Factory

- The Technical Blueprint: How It Works with DeltaStream

- Step 1: Ingest & Synchronize Data Instantly

- Step 2: On-the-Fly AI-Powered Inspection

- Step 3: Immediate, Automated Action & Continuous Improvement

- The ROI: From Cost Center to Profit Driver

In the world of high-speed manufacturing, every second counts and every product matters. Let’s consider a fictional company, Innovate Manufacturing. For companies like Innovate Manufacturing, a leader in precision-engineered components, maintaining the highest quality standards isn't just a goal; it's the bedrock of their brand. But in a facility producing thousands of parts per hour, how do you catch a microscopic flaw before it becomes a million-dollar problem?

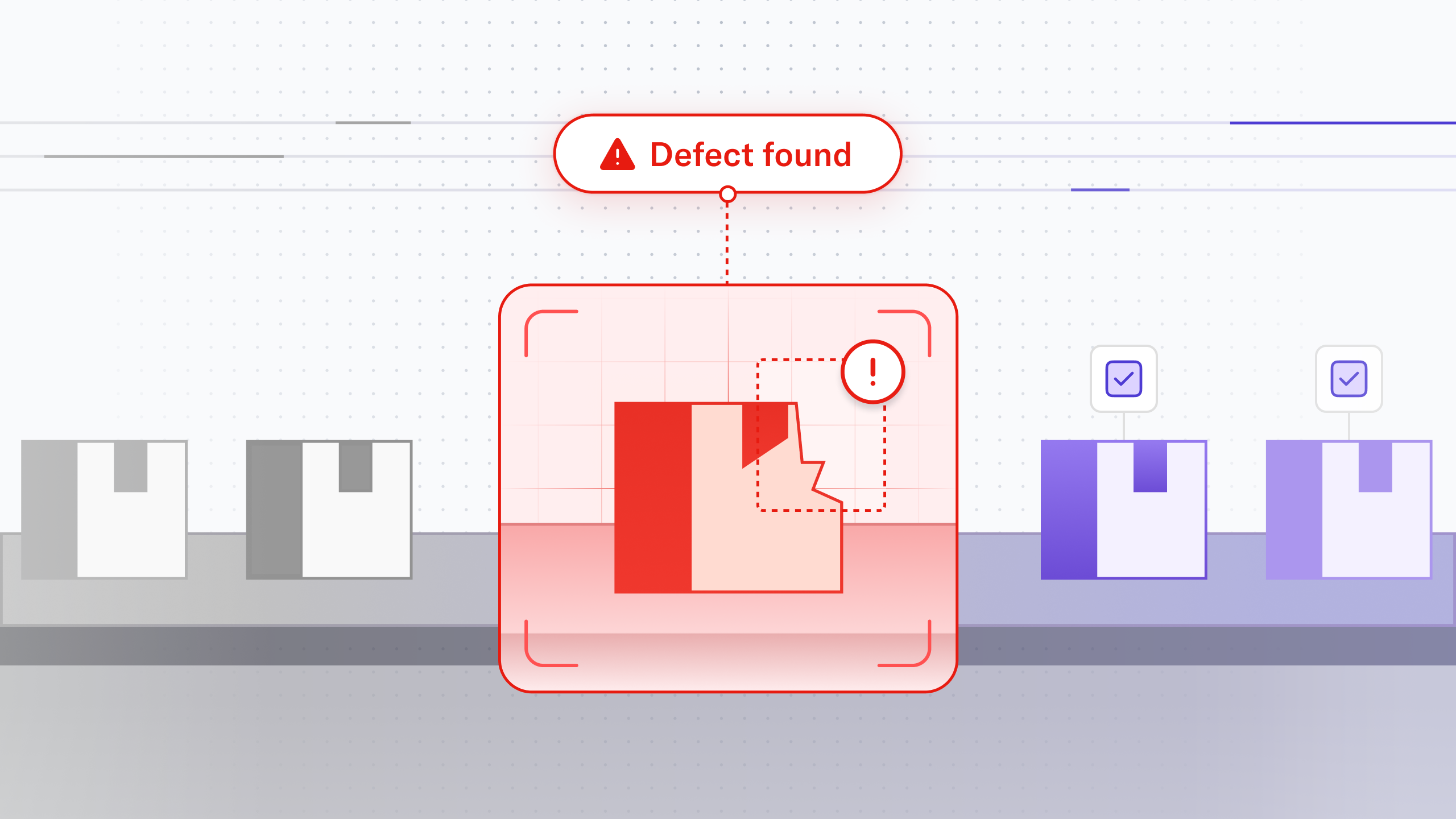

This was the challenge facing Innovate Manufacturing. Their traditional quality control, like that of many in the industry, relied on batch sampling and inspections that happened minutes—or sometimes hours—after production. A single undetected defect could contaminate an entire batch, leading to staggering amounts of scrap, costly rework, and the dreaded risk of a customer return. They needed to move from reacting to problems to preventing them in real time.

The High Cost of a Slow "No"

The core issue was a "time gap" between production and inspection. A machine could produce a faulty part, and that part, along with hundreds of others, would continue down the line, oblivious to the error. By the time a quality check flagged the issue, the damage was done. The costs were not just in wasted materials, but in:

- Manual Labor: Teams had to be diverted to sort, inspect, and rework entire batches.

- Production Halts: The entire line would often need to be paused to diagnose the root cause.

- Lost Throughput: Every minute spent on rework was a minute not spent on new production.

- Reputational Risk: The ultimate cost of a defective product reaching a customer.

Innovate Manufacturing realized they needed to give their production line instantaneous intelligence. They needed a system that could see, think, and act in milliseconds.

The Solution: A Central Nervous System for the Smart Factory

This is where DeltaStream transformed their operations. Instead of a series of disconnected steps, DeltaStream became the real-time data nervous system, connecting all the critical points of their production line into a single, intelligent flow.

The Technical Blueprint: How It Works with DeltaStream

Here’s the step-by-step implementation of a real-time inference pipeline that made this possible, all written in simple, powerful SQL.

Step 1: Ingest & Synchronize Data Instantly

First, we defined streams to ingest live data from every critical source on the factory floor.

With the sources defined, we used a temporal join to create a single, unified view of every part as it moves through the line, creating a rich "digital twin" in real time.

Step 2: On-the-Fly AI-Powered Inspection

This is where intelligence comes in. We registered a User-Defined Function (UDF) that calls a powerful vision AI model (like Google's Gemini 1.5 Pro). This function analyzes the image of each part and returns a simple "pass" or "fail" classification in milliseconds.

Step 3: Immediate, Automated Action & Continuous Improvement

Finally, we created outputs to drive action. One changelog identifies defective parts and triggers an immediate response. Another logs all failures to create a high-quality dataset for continuously retraining and improving the AI model.

An application subscribes to the defective_parts_for_action topic and sends an instant command to a robotic arm on the line. The retraining_dataset is fed back into the MLOps pipeline, creating a powerful feedback loop that makes the system smarter every day.

The ROI: From Cost Center to Profit Driver

By implementing this real-time data infrastructure, Innovate Manufacturing didn't just improve quality; they unlocked a significant and measurable return on investment.

Let's break down the numbers for a single production line:

- Reduced Scrap & Rework: Innovate Manufacturing was previously scrapping about 2% of a batch due to late-detected defects. By catching these instantly, they cut material waste by over 95%. For a line producing 1,000 parts per hour, this translates to saving thousands of parts per day.

- Annual Savings: $150,000+ in raw material and rework labor costs per line.

- Increased Throughput: Automating the rejection process and eliminating manual batch inspections freed up the line to run continuously. This resulted in a 10% increase in production capacity without adding any new machinery.

- Annual Value: $250,000+ in additional product output.

- Elimination of Manual Inspection Labor: The automated system allowed them to re-deploy three quality control officers per shift to more value-added roles like process analysis and improvement.

- Annual Savings: $180,000+ in redirected labor costs.

The implementation of the real-time inference pipeline in DeltaStream turned their quality control from a reactive cost center into a proactive, data-driven engine for efficiency and profitability. The system paid for itself in under six months and continues to deliver compounding returns as the AI models become more intelligent. For modern manufacturers, the future of quality isn't about more inspectors; it's about smarter, faster data. By leveraging a real-time stream processing platform like DeltaStream, companies can build a truly intelligent factory that not only prevents errors but also drives significant, measurable ROI.

The runnable DeltaStream SQL code for this use case is available at https://github.com/deltastreaminc/examples.

This blog was written by the author with assistance from AI to help with outlining, drafting, or editing.